Today, I want to take you on a journey through my multi-year adventure with an extraordinary project —FabEdu. This initiative allowed me to be at the forefront of educational innovation, collaborating with a diverse array of research partners throughout Europe. Our mission? To push the boundaries of what’s possible in STEM education. Along this path, I’ve encountered some exceptional highlights that I’m thrilled to share with you.

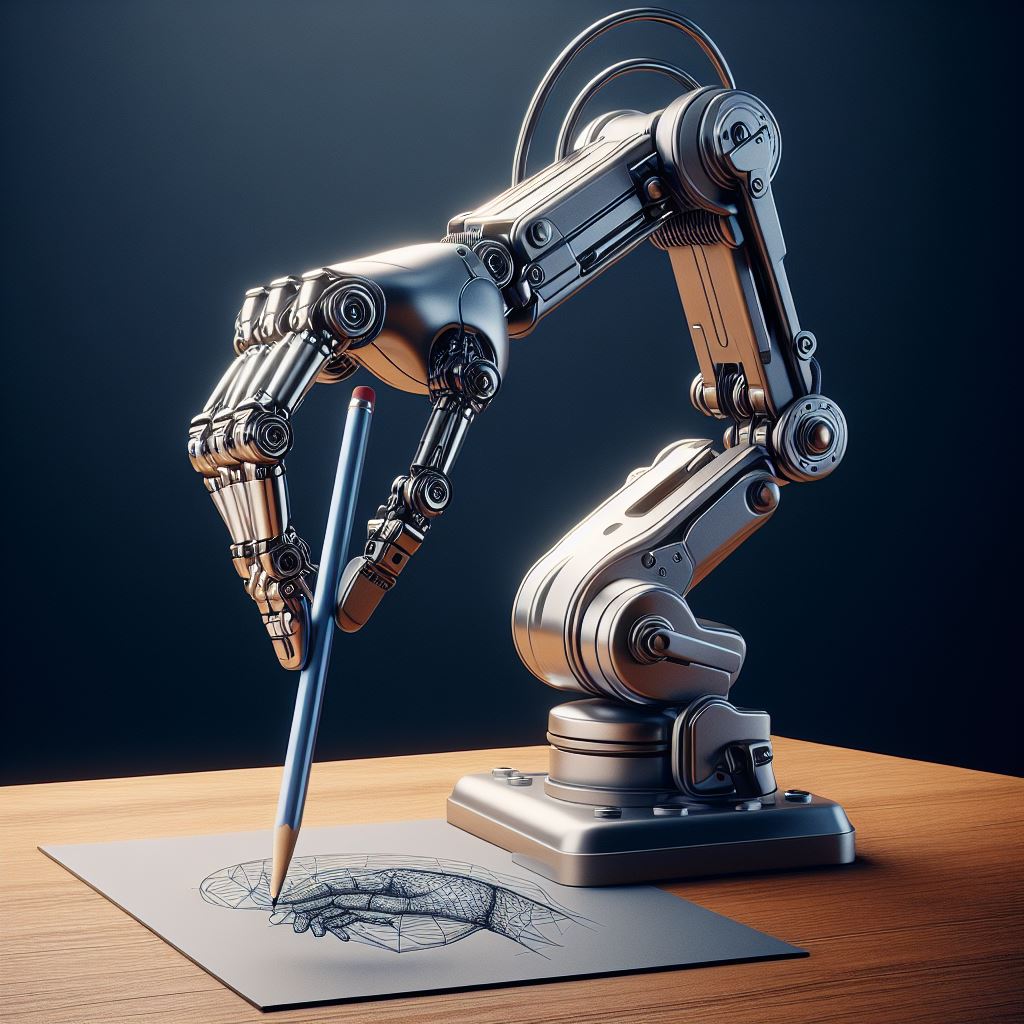

Piccolo: A Compact Robotic Artist

Imagine a small robotic system armed with three servo motors and blessed with the ability to move freely across three axes (x, y, z). This is Piccolo, a charming device that can sketch out intricate shapes and letterforms. Based around an Arduino board, Piccolo is easily controlled via any Arduino-compatible programming environment, such as Scratch4Arduino or mBlock.

Manual Drawing Plotter: A Step into Machine Mechanics

Stepping away from digital interfaces, we introduced participants to the mechanics of computer numerical control (CNC) machinery—a concept shared with 3D printers and laser cutters—through the manual drawing plotter. This ingeniously simple device moves a pen in two directions (horizontally and vertically) across a plane, offering a tangible understanding of CNC machine operations.

Curious and Quirky 3D-Printed Objects

Our journey also delved into the enchanting world of digital fabrication with 3D-printed objects that pique curiosity and spark imagination. These items served as an unplugged and highly accessible introduction to the realm of 3D printing, allowing participants to explore and learn without the need for complex technology.

Becoming an Einstein, One Piece at a Time

In an activity we fondly named “Become an Einstein, Step by Step,” we challenged learners to think in three dimensions. Using a 3D-printed puzzle, participants reconstructed a longitudinally cut object, piecing it together much like a three-dimensional jigsaw puzzle, thereby providing a hands-on experience with 3D printing concepts.

3D Modeling a Key to Success

Lastly, we dove into a practical application of 3D modeling. Participants designed and created their own keys, which were tailored to work within a pre-printed lock from a 3D printer. This activity was not only engaging but also demonstrated the real-world potential and utility of 3D printing technology.

The FabEdu project has been an incredibly rewarding chapter in my professional life, blending creativity with education and technology. It reinforced my belief in the power of collaborative innovation to transform learning experiences. I hope this glimpse into my work with FabEdu inspires you to think about the endless possibilities when we merge education with cutting-edge technology.